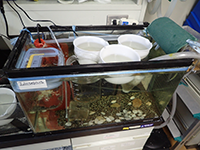

The Wet Lab.

|

| Free-standing aquarium with batches of crab zoeae (in white containers) |

Introduction

The Wet Lab.* is in Room W201, which is part of the block of aquatic laboratories belonging to the Marine Biology group of this graduate school. Included in our Wet Lab. are facilities for rearing paralarval and juvenile octopuses, and an assortment of aquaria housing various kinds of prey animals and their larvae, on which the octopuses feed. Paralarvae are brought here from the Hatchery aquarium and initially are fed mainly on crab larvae, which are produced and raised in the Crab Lab.

*[The Wet Lab. began as Lab. 2 at Amamiya (the former campus) and was moved to new facilities at Aobayama campus in February, 2017].

This lab. houses four permanent circulation systems: two identical units serving Aquaria B and C; and two identical units serving twin Aquaria D-E and F-G. Bench space accommodates other, smaller aquaria. To prevent condensation problems, the lab. room temperature is kept below those in the aquaria, and all aquaria and sumps are covered with closely-fitting lids to minimize evaporative loss.

All system aquaria generally include two in-line filters, one inserted immediately downstream of the UV sterilizer as a precaution to remove any activated particulate matter leaving the sterilizer. In particular, (i) an anecdotal account has suggested that aquarium animals are irritated by water that has passed through a UV sterilizer; and (ii) it is known that certain water-borne organics can be rendered more toxic after passing through a UV sterilizer (ref.). The in-line water filters are all wound polypropylene fibre, 5 µm (AsOne FPP-05-1), mounted in an Organo Model III 250 mm housing.

A single AP-100 air pump (Yasunaga, Tokyo) provides all the aeration in the lab. (100 litres per minute at full capacity), transferred through a system of VP 13 PVC pipes with stainless steel taps screwed into holes drilled at intervals and sealed with Esron PVC glue (Sekisui Chemical Engineering, Tokyo). The air intake filter is cleaned every 3 months or so. A bleeder outflow pipe is included to avoid excessive pressure within the system and as a safeguard against water sucking back to the pump in the event of a power failure. This bleeder pipe has its own cock for pressure adjustment and is plugged with a piece of filter material as a sound baffle.

All electrical connections pass through safety circuit breakers at the mains sockets. All seawater is artificial, made using copiously-aerated deionized tapwater and Instant Ocean synthetic sea salt supplemented with 90 µmol. l.-1 Strontium chloride (ref.).

Escapes from aquaria B & C are avoided by having a broad inner ledge around the sides of aquarium (50 mm wide, made from 8 mm transparent acrylic). This ledge also supports the lids. Similarly, aquaria F & G have a ledge along each side, composed of netting held in position with ‘hot bond.’ Escapes from the round aquaria (D & E) are discouraged by a barrier of artificial turf glued to the inside wall near the top.

|

| Front of Aquarium B |

Aquaria B & C: Specifications

| System capacity: | around 260 litres |

| Aquarium: | rectangular, 183 litres capacity |

| Sump: | rectangular, 78 litres capacity, with a small box filter and a protein skimmer |

| Main circulation: | Sanso PMD 58 Magnetic Pump (23 litres. min-1) |

| Protein skimmer: | Napqo Aquarium Systems Instant Ocean Skimm 1200 |

| Skimmer feeder pump: | NJ 2500 immersion pump (40 litres. min-1), cooled by an Enermax computer fan |

| UV sterilizer: | Lifeguard Aquatics model QL-25 |

| Heater: | 300 W immersion with separate Seapalex thermostatic control unit (Nisso Industry plc, Osaka) |

| Cooler: | Zensui ZR-130E |

Aquaria B and C were part of the first systems installed, which were purchased as a twin set from a local aquarium shop. Each is composed of a sturdy wooden cabinet supporting the aquarium on top and a sump directly beneath. The aquarium and sump are constructed from transparent acrylic (perspex).

|

| Wet Lab. Aquarium C |

Aquaria B and C: Water Circuit

Water is pumped up to the aquarium through a filter, a cooling unit, a UV sterilizer and a pre-aquarium filter. Water enters the aquarium through a VP 13 PVC pipe which passes up through the centre of the outflow duct in the rear corner of the aquarium base (so both inflow and outflow pass through the same hole in the cabinet supporting the aquarium).

To ensure efficient water circulation (since outflow is from the rear), the inflow pipe is extended horizontally to the front of the aquarium, suspended by tying it onto the mid-section cross-brace which forms a central support for the two lids of 5 mm transparent PVC (each of which covers half of the aquarium).

Outflow from the aquarium drainpipe enters a filter box mounted on top of the main sump, into which the filter box drains.

Aquaria B and C: Sump

The sump has three compartments: the small receiver section draining the filter box, communicating with the rest of the sump through an opening at the bottom of the partition into the second compartment: the first filter bed. This rests on a perforated acrylic plate. Water flows up through this first filter bed and flows over a low wall to the third compartment, housing the second filter bed, also on a perforated plate.

The filter beds are of coral pieces topped with porous ceramic cylinders. Water accumulating beneath the second filter bed is drawn out and pumped around the system.

|

| Aquarium B protein skimmer & sump |

Aquaria B and C: protein skimmer

The protein skimmer model serving aquaria B and C had many fittings, particularly tubing, made from materials considered to be toxic to cephalopods. These were mostly plastic pipes of different diameter, so they were all replaced with silicone tubing. The outflow is now a piece of flexible PVC pipe.

The tower of the skimmer provided by the aquarium shop is too tall to fit inside the sump beneath the aquarium, and fitting it into the main aquarium itself would be inconvenient and a source of problems with the octopuses being maintained (who would soon interfere with its functioning, possibly injuring themselves, and would be able to use it to climb out). Therefore, the fittings were modified to allow the skimmer to stand outside the main supporting frame, at one side of the sump. To enable correct functioning, it stands on a wooden supporting box, which in turn sits inside a larger box which retains any spills from the skimmer unit. These boxes are waterproofed by several layers of yacht varnish.

The pump driving the skimmer is an immersion pump, so it's normal functioning submerged within the sump water would enable adequate cooling to occur automatically during operation. To compensate for this and prevent overheating, the pump is air-cooled by a modified computer fan protected from water splashes by a bridge-shaped shelter made from a piece of flexible plastic plate screwed to the supporting box.

Water enters the skimmer by a tube resting in the bottom of the receiver compartment of the sump, and its outflow enters the receiver filter box adjacent to the main fall of water leaving the aquarium.

|

| Paroctopus parvus juveniles nestling among rings of VP13 piping (O.D. 18 mm) |

Uses of Aquaria B and C

These aquaria can hold 1 or 2 adult O. sinensis for a limited period.

They are mainly used for experiments with hatchling juvenile Paroctopus parvus, which are held individually or in small groups in porous pots constructed from a plastic skeleton (made by removing large areas from a 300 ml plastic beaker), lined with appropriate netting to allow water to flow through while retaining the octopuses within. These pots stand on a purpose-built PVC frame which holds them stable and upright near the surface, enabling them to be opened easily for feeding and observation. This system is obviously removed when housing O. sinensis adults.

Systems serving Aquaria D~G: Specifications

| System capacity: | around 200 litres (D & E); 145 litres (F & G) |

| Aquarium: | cylindrical, 50 litres (D & E); rectangular, 24 litres (F & G) |

| Sump: | rectangular, 95 litres capacity, with a sock filter, a protein skimmer and 2 air-lifts |

| Main circulation: | Sanso PMD-421B2M (25-32 litres. min-1) |

| Protein skimmer: | MRC model MR-1 |

| Skimmer feeder pump: | Rei-Sea RSD-40A Immersion Pump (40 litres. min-1) |

| UV sterilizer: | Iwaki UVF-1000 |

| Heater: | 300 W immersion with separate thermostatic control unit (Gex plc, Osaka) |

| Cooler: | Zensui ZR-130E |

Aquaria D~G: Construction

These four aquaria are twinned, each pair served by an identical system mounted on a supporting framework of Creform steel piping (Erector Pipe, 28 mm diameter; Yazaki Kako, plc, Shizuoka).

|

| Sump output |

All electrical connections are suspended well above the aquarium systems by vertical extensions of the supporting frame.

Air input to serve air stones and air lifts is from an overhead system of VP 13 piping from the air pump serving the lab.

As with other ports leading out from the aquaria at AiCephLab, the socket joint of the sump output to the main circulation pump is fixed with Esron PVC glue, and then sealed with ‘hot bond’. To protect the outflow tube on the inside of the sump from accidental introduction of any loose debris into the pump, the opening is covered with a piece of red netting secured with a cable tie.

Spills and overflow are confined by placing the sump and circulation pump inside a large trough (115 x 70 x 20 cm max. inner dimensions). The main circulation pump is raised off the floor of the trough on a stand to avoid submergence in the event of significant leaking.

Aquaria D~G: Water Circuit

Water removed from the sump by the main circulation pump feeds into a filter, UV sterilizer and pre-aquarium filter, each attached to a PVC plate fixed to the inside of the supporting frame.

The cooler lies under a bench placed between the twin units and is in series between the UV sterilizer and the pre-aquarium filter. The bench itself holds the protein skimmers for both units back-to-back.

Water is piped from the pre-aquarium filter to the twin aquaria through a T-branch with a cock used to adjust the flow to a bypass pipe leading directly back to the sump. A Y-branch then feeds the twin aquaria, each with its own cock to control the water input.

The water flow rate though the aquaria can therefore be adjusted flexibly as required, and even shut off to one or both aquaria, shunting surplus water through the bypass without having to turn off the circulation pump. This is useful for adjusting water flow to the aquaria and for servicing just one of the aquaria or when feeding octopuses. The bypass pipe takes any excess water diverted from the aquaria back into the sump, arriving via a third pipe entering the sump (the other two being the drains from each of the aquaria).

Aquaria D~G: Sump

The outflow from each aquarium is piped directly into a sock filter in the receiver compartment of the sump through tightly fitting holes in the lid. Apart from the sock filter (suspended from a supporting plate just below the lid), the receiver unit contains only water except for a heater and its thermostat sensor, and the immersion pump feeding the protein skimmer (plastic bolts and fittings glued to the floor of the unit hold the pump and heater in position).

|

|

Aquaria D~E receiver box with immersion pump, heater & its thermostat sensor |

|

| Aquaria D~E sump receiver box lid (upside down) |

|

|

Aquaria D~E sump receiver box filter sock support plate |

|

|

Aquaria D~E sump filter bed during assembly. Note airlift pipes, & support rods for top plate |

|

The main flow then passes to the skimmer, with an opening beneath the central partition of the sump allowing equalization of water levels between the receiver and filter-bed compartments of the sump.

|

|

Filter box top plate (receives skimmer output) |

|

|

Filter box bottom plate (filter bed support plate) |

The inflow to the skimmer is from an immersion pump in the sump receiver compartment. The outflow passes through a VP-30 pipe, through the sump lid into the central head of the filter-bed compartment, which has a custom-built gadget glued to the centre of the top plate. This gadget disperses the skimmer outflow evenly over the top plate, which is perforated with 8 mm diameter holes.

|

| Airstone clearance |

The top plate rests on a series of long PVC rods attached to the bottom plate supporting the filter bed. A handle screwed to the centre of the bottom plate allows it to be removed for servicing.

Water percolates down through the filter bed (porous ceramic cylinders), which rests on the perforated bottom plate, itself held off the bottom by short columns of square PVC rod glued to its underside.

Water is circulated through 2 vertical airlifts at opposite corners of the filter-bed compartment (these are VP-20 PVC pipes resting on the base of the sump with holes near the bottom, and a 15 mm diam. airstone powering the lift). Water underneath the filter bed feeds the inlet of the main circulation pump.

|

| Partially built aquarium system D~G: back-to-back skimmers; bypass & Y-branch tubes serving aquaria D~E (insulated yellow tubs with ring of artificial turf) |

Aquaria D and E: Construction

Each of these aquaria is a lidded cylindrical plastic pickle tub of 70 litres capacity, with a barrier of artificial turf glued to the inside wall near the top, to discourage octopus escapes. The outside wall has a layer of insulation to inhibit heat transfer between the aquarium water and the (cooler) air of the lab.

The lid has its contact area sealed with an adhesive strip of packing material, retaining water that gathers on the underside of the lid (due to splashing from the aerator, condensation, etc.), preventing any weeping of water to the outside.

The inflow to the aquarium passes through the lid via two PVC VP 13 L-pieces (one on the outside and one on the inside of the lid) into a length of silicone tubing spiralling round the inside of the lid, held with plastic cable ties passing through the lid. The tubing is perforated by holes made with a leather punch, such that water enters with its energy dissipated as a shower. The end of the tubing is closed with a VP 13 PVC end-piece glued to a short piece of VP 13 PVC piping held in the end of the tubing with a plastic cable tie.

The aquarium outflow is from a PVC fitting located centrally and glued in position, with a small hoop of packing material to maintain a water-tight seal. The water level in the aquarium is determined by suspending a loop of outflow tubing on the aquarium frame before directing it into the receiver unit of the sump. As a precaution to prevent siphoning away of the aquarium contents, the outflow pipe passes through a T-piece of PVC piping with one branch open to the atmosphere via a small aperture.

|

| Aquaria F-G |

|

| Exit from aquaria F-G |

Aquaria F and G: Construction

Each of these is a lidded polypropylene container, with a similar inlet system to aquaria D and E, except that the silicone tubing on the underside of the lid is much shorter and arranged as a semicircle, rather than a spiral.

Flow moves from the end with the silicone tube to the exit port at the opposite end of the container.

The outflow is from a fitting near the aquarium base at one side, flowing through a similar device as that in aquaria D and E to avoid siphoning.

Uses of Aquaria F and G

These aquaria house juvenile octopuses until ready for transfer to larger accommodation. However, during experiments with O. sinensis, these are replaced with yellow tubs identical to those serving twin aquaria D & E.

|

| Aquaria D~G. The lids of aquaria D & E are open while the juveniles are being fed |

Uses of Aquaria D~G

|

| Free juvenile P. parvus in aquarium D |

Aquaria D~G house free-swimming O. sinensis paralarvae, or juveniles of P. parvus or A. fangsiao.

Currently, all four aquaria being used are of the D and E type (see image). Aquaria D and E contain juvenile P. parvus, which are mostly free within aquarium D, although experiments are under way with different types of accommodation. Larger juveniles prone to cannibalizing smaller siblings are housed separately in individual containers within the main aquarium.

The accompanying image shows a free aquarium-D juvenile close to a ring of VP13 piping (outer diam. 18 mm) used as a shelter. The image of aquaria D~G shows the lids of aquaria D & E open during feeding of the juveniles. (The dark matting normally shading the aquaria lids has been moved temporarily to the side and the water circulation has been diverted directly to the sump while the lids of these aquaria are suspended open).

Currently, aquarium F (furthest from the camera) has been disconnected so that maximum pump pressure can be used to maintain a stronger flow of water to aquarium G, which has been modified following the principles outlined in a recent paper (ref.). This will house paralarvae of O. sinensis, once they hatch from the eggs incubating in the hatchery.

|

| Cooled aquarium stocking hemigrapsid crabs at 15°C |

Stock of hemigrapsid crabs

Although most crabs are hatched and cultured in the Crab Lab, that facility is kept at 25°C to encourage egg production and to grow crabs and their larvae quickly. One of the aquaria in the Wet Lab. is held at 15°C with its own pump and cooler (image at right), to inhibit female crabs from producing eggs. When eggs are required, females of suitable size are selected and acclimated for introduction to aquaria in the Crab Lab.

While being stocked, trials are performed to find suitable feed for these hemigrapsid crabs, which currently are cultured on a diet of shellfish, fish offal and fresh and dried macroalgae.

|

| Large aquaria with cultures of amphipods and mysids |

Miscellaneous aquaria

Paralarval and juvenile octopuses currently cannot be cultured without being fed on living prey. However, there are no readily-available mass cultures of prey organisms that octopuses will accept: exhaustive experiments by various research groups (including ours; ref.) have led to the conclusion that the nutritional balance of Artemia (used widely with larval fin-fish) is unsuitable; and our observations suggest that copepods are rarely taken by O. sinensis paralarvae beyond their first few days of life.

|

| Small aquaria housing various intertidal animals & their larvae being assessed for ease of culturing |

Therefore, experiments are under way to culture a range of small intertidal animals and their larvae that paralarval or juvenile octopuses will readily accept as prey. Such animals must be easy to raise in large numbers and contain suitable nutrients to enable octopus paralarvae and juveniles to grow quickly and in good condition.

Currently, the stock of experimental prey organisms includes mostly shrimp and shrimp-like organisms and their larvae: mysids, grass shrimp, isopods and two different species of amphipod (one herbivorous, the other carnivorous). All have been raised more or less successfully in this lab. but some are more easily raised in large numbers than others, and some are hardier than others.

The next step is to scale up the achievements of these pilot, trial-and-error studies.